|

|

Glass inserts were Bluebonnet flowers and Monarch

butterflies. We used Bullseye glass to make them. Here my daughter,

Susannah, works on installing a

Bluebonnet.

|

Each insert was approximately 1" thick, composed

of 8 to 10 layers plus some color elements., For the

Bluebonnets, generally two layers were fused with beads on

top as color elements in the first stage of the process.

Then four of these were

assembled in a mold and fused to make the insert.

For beads, we used two colors of blue, and one neodymium glass that varied in color

from light blue to white to light pink depending on

lighting.

|

|

|

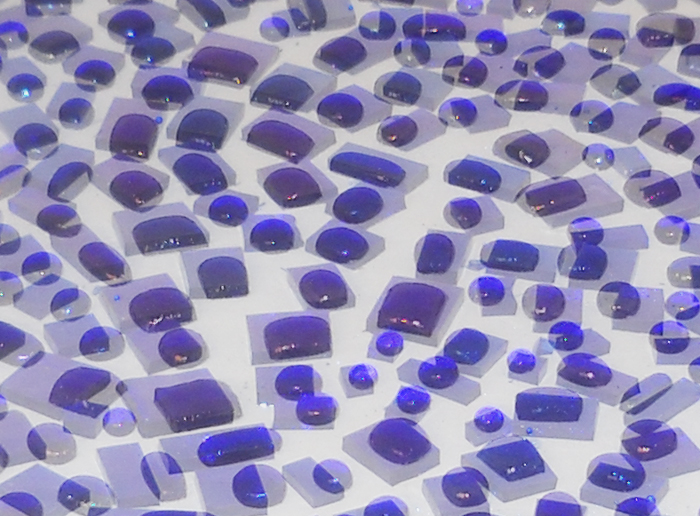

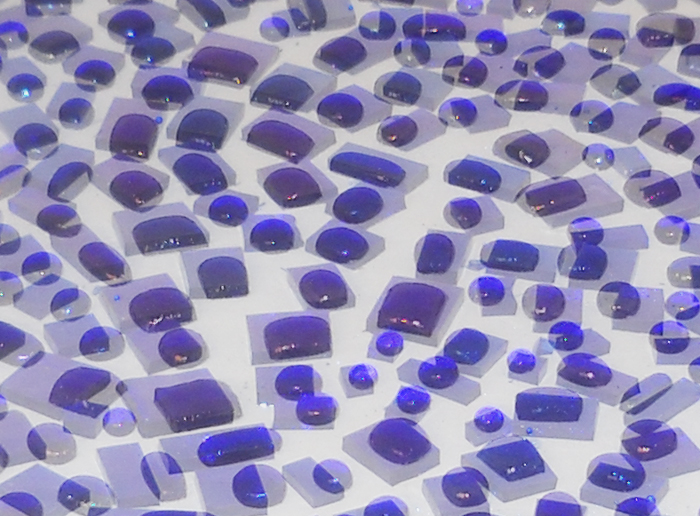

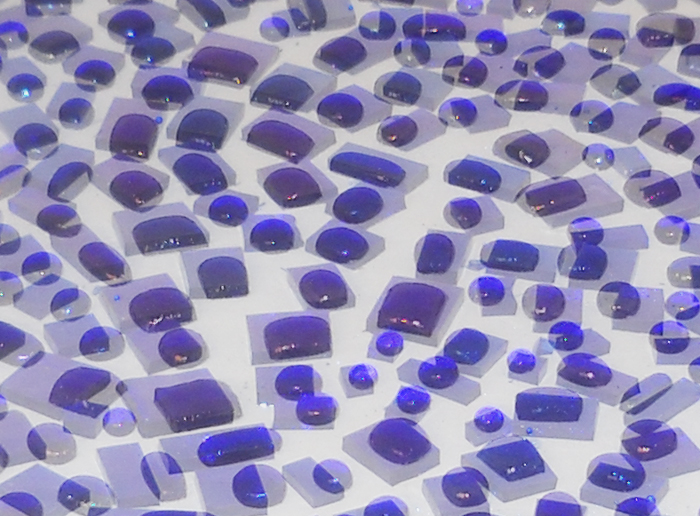

Thousands of beads were needed for the

Bluebonnets. They were cut as small squares or

rectangles. Then , in the kiln, as they melted,

surface tension caused them to "ball up" into beads. The image

above is an overlay to show the "ghost" of the original

cut shape together with the bead that it made.

|

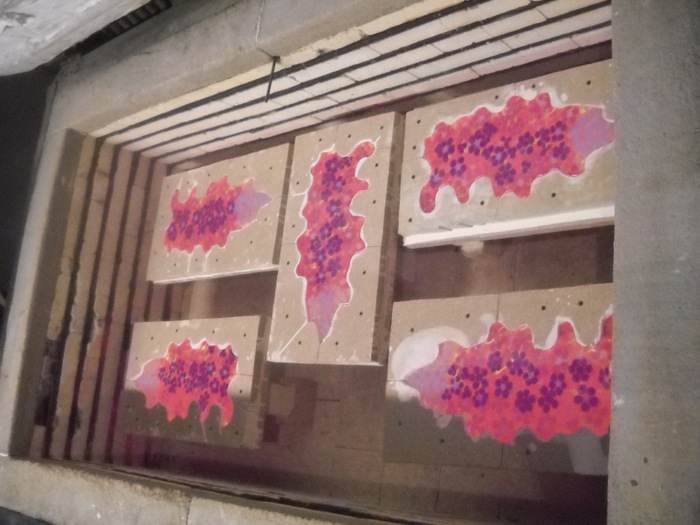

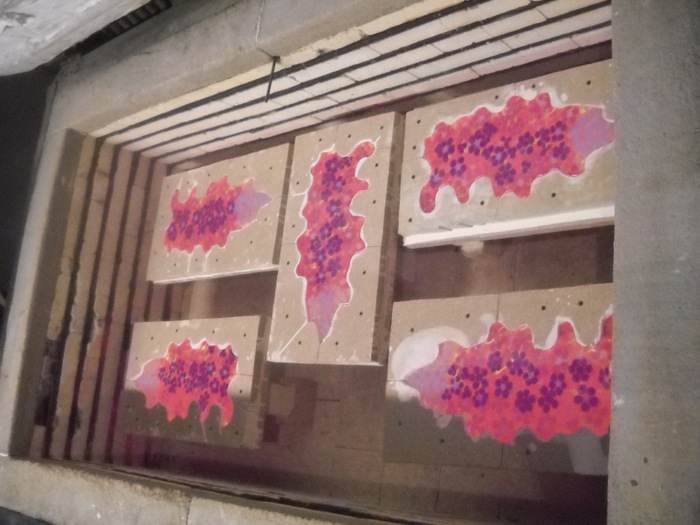

The bulk of the fusing was done with kiln space rented from

Wheaton Arts in Millville, NJ. This images shows

five Bluebonnets cooking. These molds for the second

fuse were constructed of Bullseye vermiculite board and

held together with stainless steel screws. We had

good success with

this board for molds, and also for light duty kiln

shelves. Although pre-firing the board in a kiln

with top heating elements causes it to warp, we had no

problems doing the same in these large kilns with side elements. We experienced no

warping or breakage. The kilns also worked very well

for the glass.

|

|

|

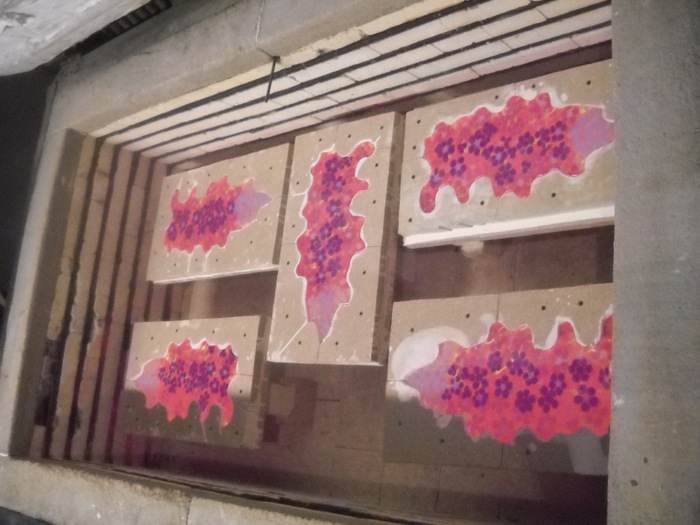

This shows six Monarchs

cooking in their final fuse.

|

And this shows them after they have cooled.

|

|

|

Monarchs required a variety of mostly smaller

white beads for some of their spots. Because these

were smaller than we wanted to cut, we made them by

quenching glass, which caused it to "crackle" in a network

of small cracks. Applying a hammer to this crackled

glass produced a frit that was in the right size range to

make the beads. We heated the glass to 900 F for 25

minutes, and quenched it in a bucket of cold water.

This is a potentially hazardous process, so we dressed in

full leathers, and used a face shield and safety glasses.

|

One side of each piece had a "matte" finish

because it was the bottom side in the kiln. These

sides were ground and polished at Glassworks Unlimited in

Greenville, Texas. We used CRL backer rod, Dow 1200

OS primer, and Dow 795 silicone to mount the

inserts. We used big cable ties to hold them in

place while the silicone set.

|

|

|

| Thank you

to Dallas Arboretum and Botanical

Garden; MKW + Associates, landscape

architects; Wheaton Arts and Cultural Center:

Glassworks Unlimited; and HC

Beck, general contractor, |

Thank you also to my family: spouse Mary Morse,

and daughters Susannah and Heidi for putting up with me

during the fabrication process, and Susannah for helping me

install. Thank you to Kate Graves for assistance in

all aspects of the fabrication. Thank you to Hank

Murta Adams for much assistance with using the kilns at

Wheaton Arts, and to Bullseye Glass for technical

assistance.

|

Home

|

|

|

|

|

|

|

|